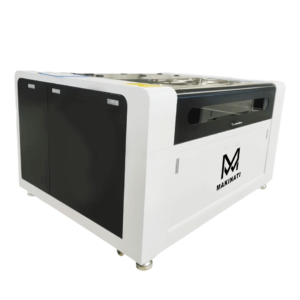

CO2 laser machine 1325 refers to a specific model size, typically indicating a larger working area of 1300 mm x 2500 mm. Makinati KSA is offering outclass quality with best efficiency. Below are some specifications of co2 laser machine.

Main Parts of the Machine:

| 1 |

Brand |

Makinati KSA |

| 2 |

Model |

WM-1325 |

| 3 |

Working Area |

1300*2500mm |

| 4 |

Control System |

Original RUIDA Control System |

| 5 |

Laser Tube |

Original Laser Tube (Power 150W) |

| 6 |

Working Table |

Knife Working Table |

| 7 |

Square Rails |

Original Square Rails |

| 8 |

Water Chiller |

CW5200 |

| 9 |

Mirrors and Lens |

Included |

| 10 |

Driving Motors |

High Speed Driving Motors |

| 11 |

Air Compressor |

Included |

Parameter:

| 1 |

Working bed |

1300 X2500mm |

| 2 |

Cooling |

CW5200 water chiller |

| 3 |

Laser power control |

1-100% software control |

| 4 |

Electricity |

AC 110-220V±10%, 60Hz |

| 5 |

Temperature |

0°-45°C |

| 6 |

Operating Humidity |

5%-95% |

| 7 |

Supported software |

DST PLT BMP DXF AI |

| 8 |

Format and software |

CORELDRAW, PHOTOSHOP, AUTOCAD, All |

| 9 |

Guide rail |

Square brand |

1. CO2 Laser machine Unrivaled Precision and Accuracy

Our CO2 laser cutting and engraving machines are designed to deliver pinpoint accuracy, allowing you to create intricate designs and detailed engravings with ease. Whether you’re working with delicate materials or need to produce complex patterns, our machines provide consistent and reliable results every time.

2. Versatility Across Materials

From wood and acrylic to leather and fabrics, our CO2 laser cutters can handle a wide variety of materials with ease. This versatility makes them ideal for a range of applications, including signage, crafts, prototyping, industrial components, and more. Expand your capabilities and take on diverse projects with confidence.

3. CO2 Laser machine Efficiency and Speed

Time is money, and our CO2 laser machines are built to maximize productivity. With high cutting speeds and minimal setup times, you can complete jobs faster and more efficiently, increasing your throughput and profitability. Experience the benefits of rapid production without sacrificing quality.

4. CO2 Laser Machine User-Friendly Operation

Designed with the user in mind, our machines feature intuitive controls and easy-to-use software. Whether you’re a seasoned professional or new to laser cutting, you’ll find our systems straightforward to operate, reducing the learning curve and helping you get started quickly.

5. Superior Build Quality

Invest in a machine that stands the test of time. Our CO2 laser cutters are constructed with high-quality components and robust engineering, ensuring durability and long-term reliability. Benefit from reduced maintenance and consistent performance year after year.

CO2 Laser Cutting Machine

How It Works

A CO2 laser cutting machine operates by generating a high-energy laser beam using a mixture of gases (primarily carbon dioxide) excited by electrical energy. This laser beam is then directed through a series of mirrors and lenses to focus on a specific point on the material, causing it to melt, burn, or vaporize, resulting in a precise cut or engraving.

Key Components

- Laser Tube: The heart of the machine, containing the CO2 gas mixture that generates the laser beam.

- Power Supply: Provides the electrical energy needed to excite the gas mixture in the laser tube.

- Mirrors: Used to direct the laser beam from the tube to the cutting head.

- Focusing Lens: Concentrates the laser beam into a fine point to achieve high precision.

- Cutting Head: The part of the machine where the focused laser beam interacts with the material.

- Cutting Bed: The platform where the material to be cut or engraved is placed.

- Control System: Includes software and hardware to control the movement of the laser head and the operation of the machine.

- Exhaust System: Removes smoke, fumes, and debris produced during the cutting process.

- Cooling System: Keeps the laser tube and other components at a stable temperature to prevent overheating.

Materials Suitable for CO2 Laser Machine

- Wood

- Acrylic

- Plastics

- Leather

- Fabrics

- Paper and cardboard

- Glass (engraving only)

Applications of co2 laser machine

- Signage and Advertising: Cutting and engraving signs, logos, and displays.

- Art and Craft: Creating intricate designs, custom artwork, and craft projects.

- Prototyping: Rapid prototyping of models and parts.

- Industrial Applications: Cutting gaskets, seals, and other components.

- Customization: Personalizing products with names, logos, or designs.

- Textile Industry: Cutting fabrics for clothing and accessories.

- Packaging: Creating custom packaging solutions.

Advantages of CO2 Laser Machine

- High Precision: Can create intricate and detailed cuts and engravings.

- Versatility: Can handle a wide range of materials.

- Non-Contact Process: Reduces the risk of material damage and wear on the machine.

- Speed and Efficiency: High cutting speeds and efficient production.

- Quality: Produces clean edges with minimal post-processing required.

Considerations

- Initial Cost: CO2 laser cutting machines can be expensive to purchase and set up.

- Maintenance: Requires regular maintenance to ensure optimal performance, including cleaning lenses and mirrors and replacing the laser tube periodically.

- Safety: Proper safety measures must be followed, including using appropriate ventilation and protective equipment to handle fumes and laser radiation.

- Material Limitations: While CO2 lasers can cut a wide range of materials, they are less effective on thicker metals without specialized setups.

Safety Measures

- Always wear appropriate protective eyewear to shield eyes from laser radiation.

- Ensure proper ventilation and use exhaust systems to remove harmful fumes and smoke.

- Follow manufacturer guidelines for operation and maintenance.

- Keep the work area clean and free of flammable materials.

CO2 laser machines are powerful tools widely used in various industries for their precision, versatility, and efficiency. They are essential for applications requiring intricate designs, rapid prototyping, and customization.

Key Features

- High-Power CO2 Laser Tube: Provides powerful and precise cutting capabilities.

- Advanced Control System: Easy-to-use software for designing and executing cuts.

- Adjustable Cutting Bed: Accommodates various material sizes and thicknesses.

- Safety Features: Integrated exhaust system and protective measures for safe operation.

- Cooling System: Maintains optimal temperature for consistent performance.

Applications

- Signage and Advertising: Create eye-catching signs, displays, and promotional materials.

- Arts and Crafts: Bring your creative visions to life with detailed cuts and engravings.

- Prototyping: Develop and refine prototypes quickly and accurately.

- Industrial Components: Manufacture gaskets, seals, and other precise parts.

- Customization: Personalize products with names, logos, and intricate designs.

- Textile Cutting: Produce clothing and accessories with precision cuts.

Hear from Our Satisfied Customers of CO2 Laser Machine

“Switching to a CO2 laser machine has revolutionized our production process. The precision and speed are unmatched, and the versatility allows us to take on new projects we couldn’t handle before.” – [Abu Taha]

Take Your Business to the Next Level

Don’t miss out on the opportunity to enhance your operations with Makinati ksa top-of-the-line CO2 laser machines. Contact us today to learn more, request a demo, or get a personalized quote. Experience the difference that precision, efficiency, and versatility can make.

Invest in the best. Choose our CO2 laser cutting and engraving machines for superior performance and exceptional results.