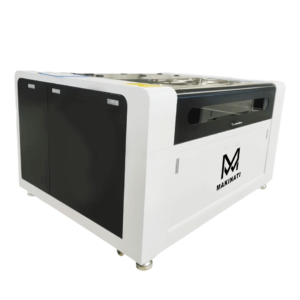

CNC routers are versatile machines used in various industries because of that Makinati KSA Company offering cnc router in jeddah, riyadh, makkah, Madina and in all cities of saudi arabia:

Makinati is offering CNC Router in jeddah and other cities of saudi arabia which you can use for Cutting, shaping, and engraving wood for furniture, cabinetry, and decorative items. CNC Router reduce manpower and increase production. CNC Router work efficiently and give you outclass results.

Machining parts for automotive, aerospace, and industrial applications.

Makinati KSA Provide CNC Router which can use for Cutting and forming parts for consumer products, packaging, and prototyping.

Engraving and cutting materials like acrylic, plastic, and wood for signs and displays.

Creating detailed engravings, custom jewelry, and other intricate designs.

| 1 | Spindle | Original 6.0KW HSD Air Cooling Spindle |

| 2 | Control System | OriginalA11 DSP Control System |

| 3 | Driving Motors and

Drivers |

XAxis: 1500W Leadshine Servo Motor+ Driver |

| YAxis: 1500W Leadshine Servo Motor+ Driver | ||

| ZAxis: 1500W Leadshine Servo Motor+ Driver+Brake | ||

| 4 | Control System | Original 4000E Controller |

| 5 | Ball Screw | High Precision Taiwan Designed Ball Screw |

| 6 | Rails | High Precision HIWIN Square Rails |

| 7 | Blocks | High Precision HIWIN Blocks |

| 8 | Rack and Opinion | HighPrecision Taiwan Designed Helical Tooth |

| 9 | Machine Structure | HeavyDutyStructure and Strong Structure (Double Strengthened

Structure) |

| 10 | Spindle quantity | One Spindle |

| 11 | WorkingTable | T-slotandVacuumCombined Working Table |

| 12 | Electronics | Original France Schneider Brands |

| 13 | Tool Sensor | Included |

| 14 | DustCollector | IPad computer licensed software |

| 1 | Max. engraving area | 2100*6000*300mm |

| 2 | Acceptable material

thickness |

300mm |

| 3 | Working table | T-slotandVacuumCombined Working Table |

| 4 | Working table size | 2100mm*6000mm |

| 5 | Processing resolution | ±0.1mm |

| 6 | Re positioning resolution | ±0.02mm |

| 7 | Spindle motor | Original 6.0KW HSD Air Cooling Spindle |

| 8 | Spindle rotating speed | 18000rpm |

| 9 | Transmitting system | XY axis Rack and Opinion+ Square guide; Z axis ball screw+ Square

guide |

| 10 | Driving motor | 1500W Leadshine Servo Motor+ Driver |

| 11 | Power consumption | 2.0KW(Without Spindle) |

| 12 | Empty Traveling Speed | ≥40000mm/min |

| 13 | Processing Speed | ≥20000mm/min |

| 14 | Spindle Quantity | 1 spindle |

| 15 | Control system | A11 DSP Control System (Original Brand) |

| 16 | Format | G code |

| 17 | Voltage | 3 Phase 380V, 50HZ |

| 18 | Surroundings | Temperature: 0-45℃; humidity:30%-75% |

| 19 | Net Weight | 3350KG |

| 20 | Packing Size | 6550mm*2290mm*1900mm |

In a CNC router, particularly one with a model designation like 2160, you might expect the following features same Makinati ksa mention below :

If “CNC router 2160” is a specific model from a particular manufacturer, checking the manufacturer’s website www.makinatiksa.com.

Makinati KSA Company will provide its customer CNC (Computer Numerical Control) router which is computer-controlled cutting machine used for various materials, including wood, metal, plastic, and foam. It automates the cutting process by following a programmed set of instructions, ensuring precision and repeatability. CNC routers are highly versatile and find applications in many industries.

To begin with, a CNC router consists of several key components. The frame provides the structural support, while the spindle is the rotating cutting tool that does the actual cutting. The drive system, often composed of stepper or servo motors, moves the spindle along the X, Y, and Z axes. Moreover, the controller interprets the G-code (the programming language) and directs the drive system accordingly. Additionally, the worktable holds the material in place, and software (both CAD and CAM) is used to design the workpieces and generate the toolpaths.

Firstly, you create a design using CAD (Computer-Aided Design) software. Then, this design is converted into a series of commands using CAM (Computer-Aided Manufacturing) software. These commands are written in G-code, which the CNC router’s controller reads. Consequently, the controller sends signals to the drive system, which moves the spindle and cutting tool along the specified paths to shape the material.

CNC routers are used in a wide array of industries. For example, in woodworking, they can create intricate designs and carvings for furniture and cabinetry. Additionally, metalworking industries use CNC routers to cut and shape metal parts with high precision. Furthermore, the sign-making industry relies on CNC routers to produce detailed signs and lettering.

Firstly, CNC routers offer unmatched precision and accuracy, which is crucial for producing detailed and complex designs. Secondly, they are highly efficient, capable of working continuously without fatigue, thus increasing productivity. Additionally, CNC routers provide consistency, ensuring each piece is identical, which is particularly important in mass production.

When selecting a CNC router, it is essential to consider several factors. For instance, the size of the cutting area should match your project requirements. Furthermore, the power of the spindle determines the types of materials you can work with. Besides, the quality of the drive system impacts the precision and speed of the machine. Additionally, ensure the router is compatible with your preferred CAD/CAM software.

In summary, CNC routers are powerful, versatile tools used across various industries for cutting and shaping materials. They offer high precision, efficiency, and consistency, making them indispensable in modern manufacturing and crafting. By understanding their components, operation, and applications, you can effectively utilize CNC routers to enhance your production capabilities.

85,000 ر.س